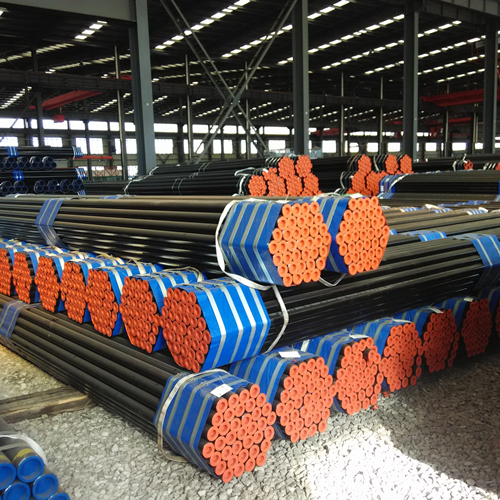

API 5L X70 Pls2 Carbon Welded Mild Ms Black Annealing ERW Steel Pipe

Key Specifications / Features

Model no.: HX-LINE PIPE-75 Hits: 22

China Manufacturer of API 5L X70 Pls2 Carbon Welded Mild Ms Black Annealing ERW Steel Pipe

Request a quote

share

Tags

Previous: API 5CT J55 4IN 11.6PPF Tubing Pipe

Detail Information

Standard: API 5L-2009 ISO 3183-2007 DIN 30670 ( Coating)

Steel Grades: Gr. B X42 X46 X52 X56 X60 X65 X70 L245 L290 L320 L360 L390 L415 L450 L480

Size Range: OD:1/2” TO 24”. WT: 3mm To 45mm

Manufacturing Process : Hot Rolled / Hot Expansion/

Application:The external coating is mainly used for anti-corrosion protection for liquid pipes before burying.Such pipes has been widely used in rugged environment

Packing: External Black Painting ,Both Side With End Caps, In Bundles by Steel Strips,Covered by Waterproof.

specifiction:

Line pipe for sour service are produced with pure, fully killed, fine grain steel. The content of sulphur, phosphor and other harmful elements is strictly controlled. Meanwhile elements Nb, V, Al and other alloy elements have been added. The pipe has not only high resistance against H2S, but also have better performance of mechanical properties, hardness, breaking toughness, fatigue resistance and crack prevention ability. The test result of SSC (NACE TM0177-2005) AND HIC (NACE TM0284-2003) have reached the requirements of API 5L (44th edition) Annex H after the inspection of competent authorities. This kind of pipe can fully meet the demand of NACE MR0175 or ISO 15156.

Steel Grades: Gr. B X42 X46 X52 X56 X60 X65 X70 L245 L290 L320 L360 L390 L415 L450 L480

Size Range: OD:1/2” TO 24”. WT: 3mm To 45mm

Manufacturing Process : Hot Rolled / Hot Expansion/

Application:The external coating is mainly used for anti-corrosion protection for liquid pipes before burying.Such pipes has been widely used in rugged environment

Packing: External Black Painting ,Both Side With End Caps, In Bundles by Steel Strips,Covered by Waterproof.

specifiction:

Line pipe for sour service are produced with pure, fully killed, fine grain steel. The content of sulphur, phosphor and other harmful elements is strictly controlled. Meanwhile elements Nb, V, Al and other alloy elements have been added. The pipe has not only high resistance against H2S, but also have better performance of mechanical properties, hardness, breaking toughness, fatigue resistance and crack prevention ability. The test result of SSC (NACE TM0177-2005) AND HIC (NACE TM0284-2003) have reached the requirements of API 5L (44th edition) Annex H after the inspection of competent authorities. This kind of pipe can fully meet the demand of NACE MR0175 or ISO 15156.

| DELIVERY CONDITION | |

| Steel grade | Delivery condition |

| BNS(L245NS) | Normalizing rolled, normalizing formed, normalized, normalized and tempered |

| X42NS(L290NS) | Normalizing rolled, normalizing formed, normalized, normalized and tempered |

| X46NS(L320NS) | Normalizing rolled, normalizing formed, normalized, normalized and tempered |

| X52NS(L360NS) | Normalizing rolled, normalizing formed, normalized, normalized and tempered |

| BQS(L245QS) | Quenched and tempered |

| X42QS(L290QS) | Quenched and tempered |

| X46QS(L320QS) | Quenched and tempered |

| X52QS(L360QS) | Quenched and tempered |

| X56QS(L390QS) | Quenched and tempered |

| X60QS(L415QS) | Quenched and tempered |

| MECHANICAL PROPERTIES | |||||||

| Steel Grade | Strtch Performance | Impact energy(J) |

Hardness | ||||

| Yield strength | Tensile strength | Elongation | |||||

| Mpa | Mpa | % | Min | Max | |||

| Min | Max | Min | Max | ||||

| BNS(L245NS) BQS(L245QS) | 245 | 450 | 415 | 760 | As per standard |

27 | 22HRC OR 250HV10 |

| X42NS(L290NS) X42Q(L290QS) | 290 | 495 | 415 | 760 | 27 | ||

| X46NS(L320NS) X46Q(L320QS) | 320 | 525 | 435 | 760 | 27 | ||

| X52NS(L360NS) X52Q(L360QS) | 360 | 530 | 460 | 760 | 27 | ||

| X56QS(L390QS) | 390 | 545 | 490 | 760 | 27 | ||

| X60QS(L415QS) | 450 | 600 | 520 | 760 | 27 | ||

Comment Form